The Basics of Plastic Injection Molding: A Beginner's Guide

Plastic injection molding is a widely used manufacturing process that involves injecting molten plastic into a mold cavity. It is a versatile and efficient method for producing high-quality plastic parts and products. In this comprehensive guide, we will explain the fundamentals of plastic injection molding, making it accessible for those new to the process.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing process that allows for the production of a wide range of plastic parts and products. It involves injecting molten plastic material into a mold cavity, where it cools and solidifies to form the desired shape. The process is highly automated and can be used to produce complex and intricate designs with high precision.

How Does Plastic Injection Molding Work?

The plastic injection molding process consists of several steps:

Step 1: Clamping

The mold, which consists of two halves, is securely clamped together. This ensures that the mold remains closed during the injection and cooling process.

Step 2: Injection

Molten plastic material is injected into the mold cavity through a nozzle and runner system. The material fills the cavity and takes the shape of the mold.

Step 3: Cooling

The molten plastic material cools and solidifies inside the mold cavity. Cooling time is an important factor in the process, as it affects the quality and dimensional accuracy of the final product.

Step 4: Ejection

Once the plastic has cooled and solidified, the mold opens, and the finished product is ejected. Ejection can be done manually or with the help of ejector pins or plates.

Why Choose Plastic Injection Molding?

Plastic injection molding offers several advantages over other manufacturing processes:

1. Cost-effective: Plastic injection molding is a cost-effective method for producing large quantities of plastic parts.

2. Versatile: It can be used to produce a wide range of plastic parts with varying sizes, shapes, and complexities.

3. High precision: The process allows for the production of parts with high dimensional accuracy and tight tolerances.

4. Material options: Plastic injection molding supports a variety of plastic materials, including thermoplastics and thermosetting plastics.

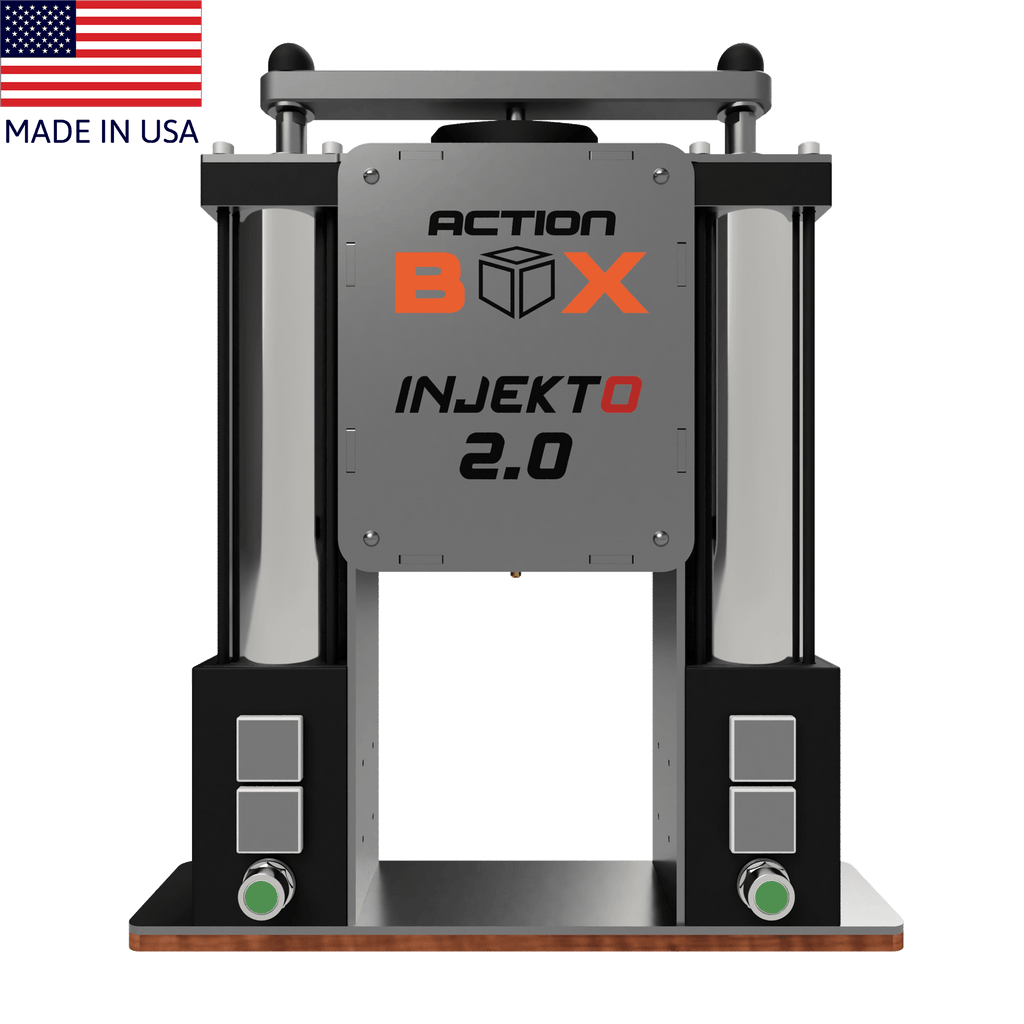

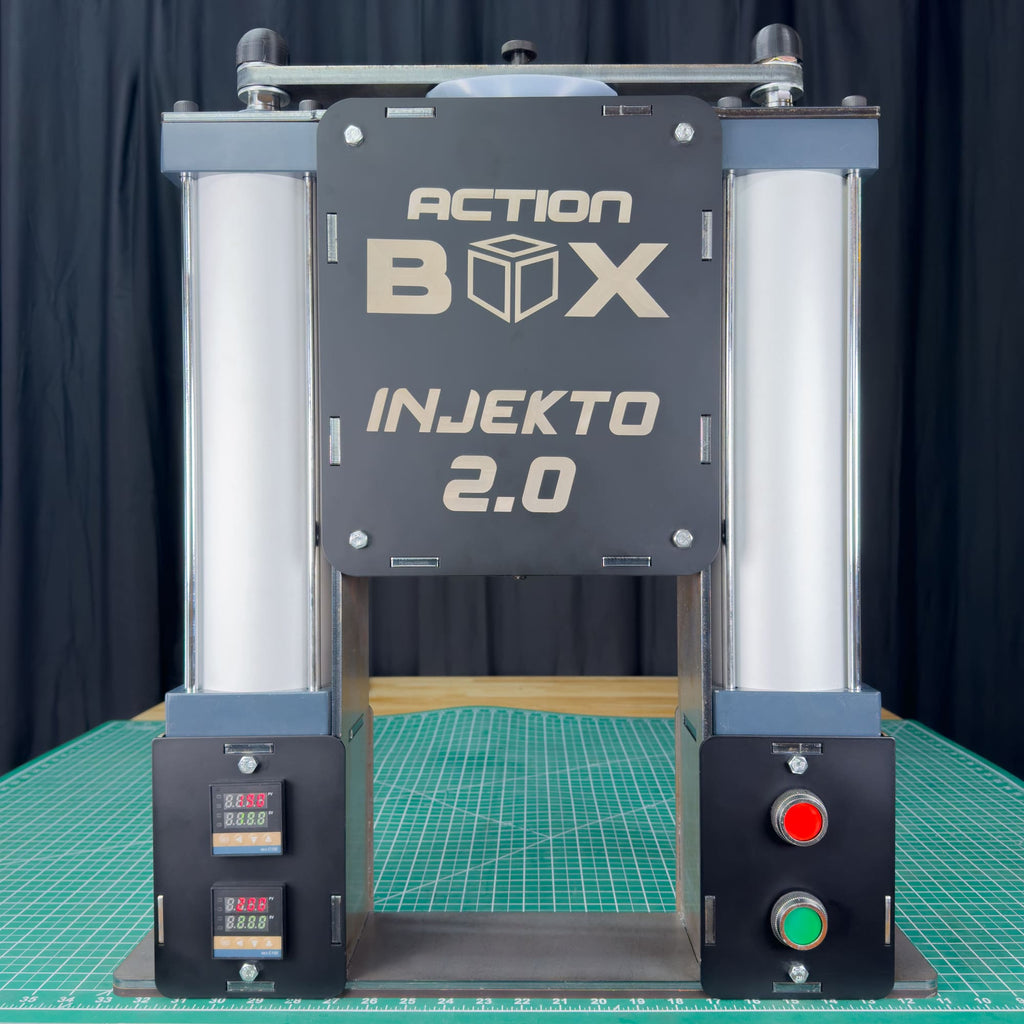

Introducing INJEKTO 2.0

If you are new to plastic injection molding and looking to get started at a low cost and for rapid prototyping, INJEKTO 2.0 is the perfect solution. INJEKTO 2.0 is a user-friendly and affordable plastic injection molding machine that is designed for small-scale production and prototyping. With its intuitive interface and compact size, it is ideal for beginners and professionals alike.

In conclusion, plastic injection molding is a versatile and efficient manufacturing process for producing high-quality plastic parts and products. By understanding the fundamentals of the process, you can make informed decisions and leverage the benefits it offers. Whether you are a hobbyist, entrepreneur, or industry professional, INJEKTO 2.0 can help you embark on your plastic injection molding journey.

Contact us if you're interested in our machine kits. We're happy to assist.