Safety First: A Guide to Using INJEKTO 2.0 Safely

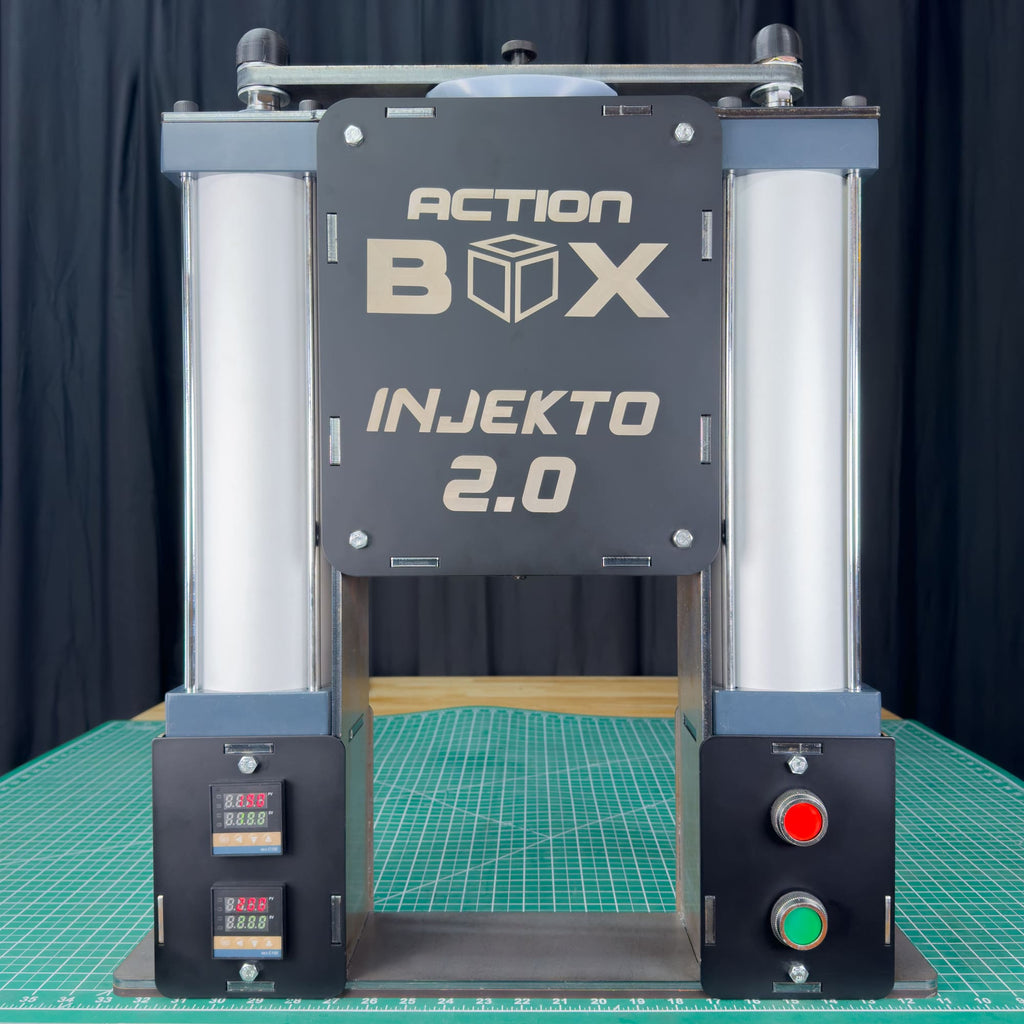

The INJEKTO 2.0 Desktop Plastic Injection Machine offers an exciting opportunity for DIY enthusiasts and small-scale manufacturers to create plastic parts and prototypes with ease. However, it's essential to prioritize safety when working with any kind of machinery, and the INJEKTO 2.0 is no exception. In this guide, we'll emphasize the importance of safety while using INJEKTO 2.0 and provide you with a comprehensive set of safety measures and precautions to follow.

Why is Safety Important?

When working with any machinery, including the INJEKTO 2.0, safety should never be taken lightly. Here are a few reasons why safety is of utmost importance:

- Prevent Accidents: Following safety measures reduces the risk of accidents and injuries.

- Protect Yourself and Others: Safety precautions not only safeguard you but also those around you.

- Preserve the Machine: Proper safety practices ensure the longevity and optimal performance of the INJEKTO 2.0.

Essential Safety Measures and Precautions

Now that you understand the significance of safety, let's dive into the essential safety measures and precautions to follow when using the INJEKTO 2.0:

1. Wear Protective Gear

Always wear appropriate personal protective equipment (PPE) when using the INJEKTO 2.0. This includes safety glasses, gloves, and a lab coat or apron. PPE helps minimize the risk of injuries from flying debris or accidental plastic spills.

2. Ensure Proper Ventilation

Operate the INJEKTO 2.0 in a well-ventilated area to prevent the accumulation of fumes or hazardous gases. Adequate ventilation helps maintain a safe working environment.

3. Follow Electrical Safety Guidelines

When connecting the INJEKTO 2.0 to a power source, ensure the machine is properly grounded. Avoid using damaged power cords and always unplug the machine when not in use.

4. Handle Materials with Care

When working with plastic materials, exercise caution. Follow proper and reasonable temperature and pressure settings to prevent material degradation or machine malfunction. Avoid touching hot surfaces and use tools or gloves when necessary.

5. Regular Maintenance and Inspections

Regularly inspect INJEKTO 2.0 for any signs of wear, loose parts, or leaks. Promptly address any issues to ensure safe and efficient operation.

6. Emergency Preparedness

Be prepared for emergencies. Keep a fire extinguisher nearby and know how to use it. Familiarize yourself with the location of emergency shut-off switches at your workshop and procedures to follow in case of an accident.

Conclusion

Using the INJEKTO 2.0 desktop plastic injection machine can be a rewarding experience, but safety should always be your priority. By following the safety measures and precautions outlined in this guide, you can ensure a safe and productive working environment. Remember, a responsible and cautious approach is key to preventing accidents and enjoying the benefits of the INJEKTO 2.0.