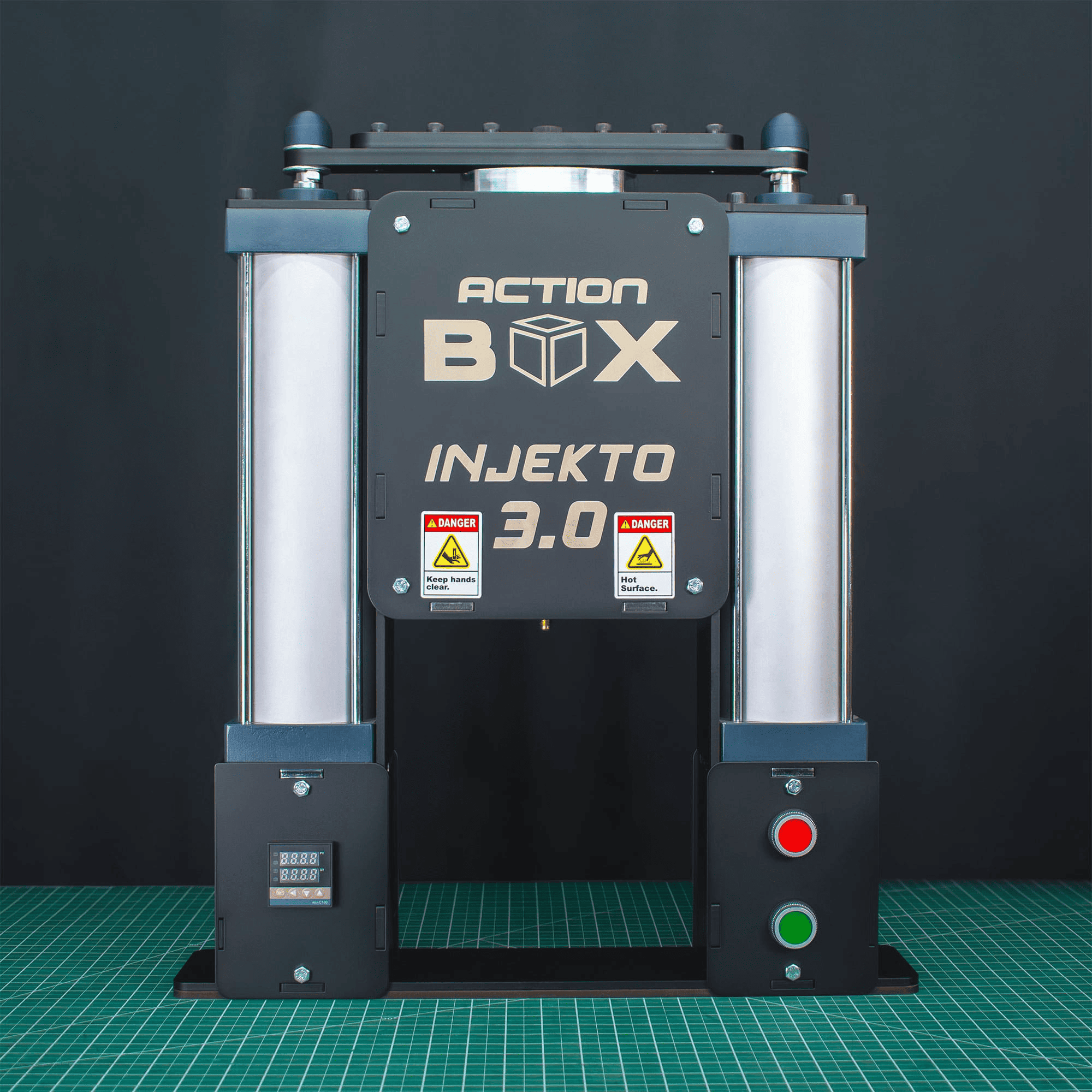

INJEKTO 2 | DIY Injection Molding | Make Parts With This DIY Plastic Injection Machine Kit

INJEKTO 3 KITS ARE NOW AVAILABLE FOR PURCHASE

After inventing our original desktop plastic injection machine, we promised you all an improved version that can be used with 3D printed molds, and we delivered.

This machine works great in tandem with SHREDII 6, our DIY plastic shredder recycling machine, to turn old 3D prints and other plastic waste into pellets that can then be injected into 3D printed molds.

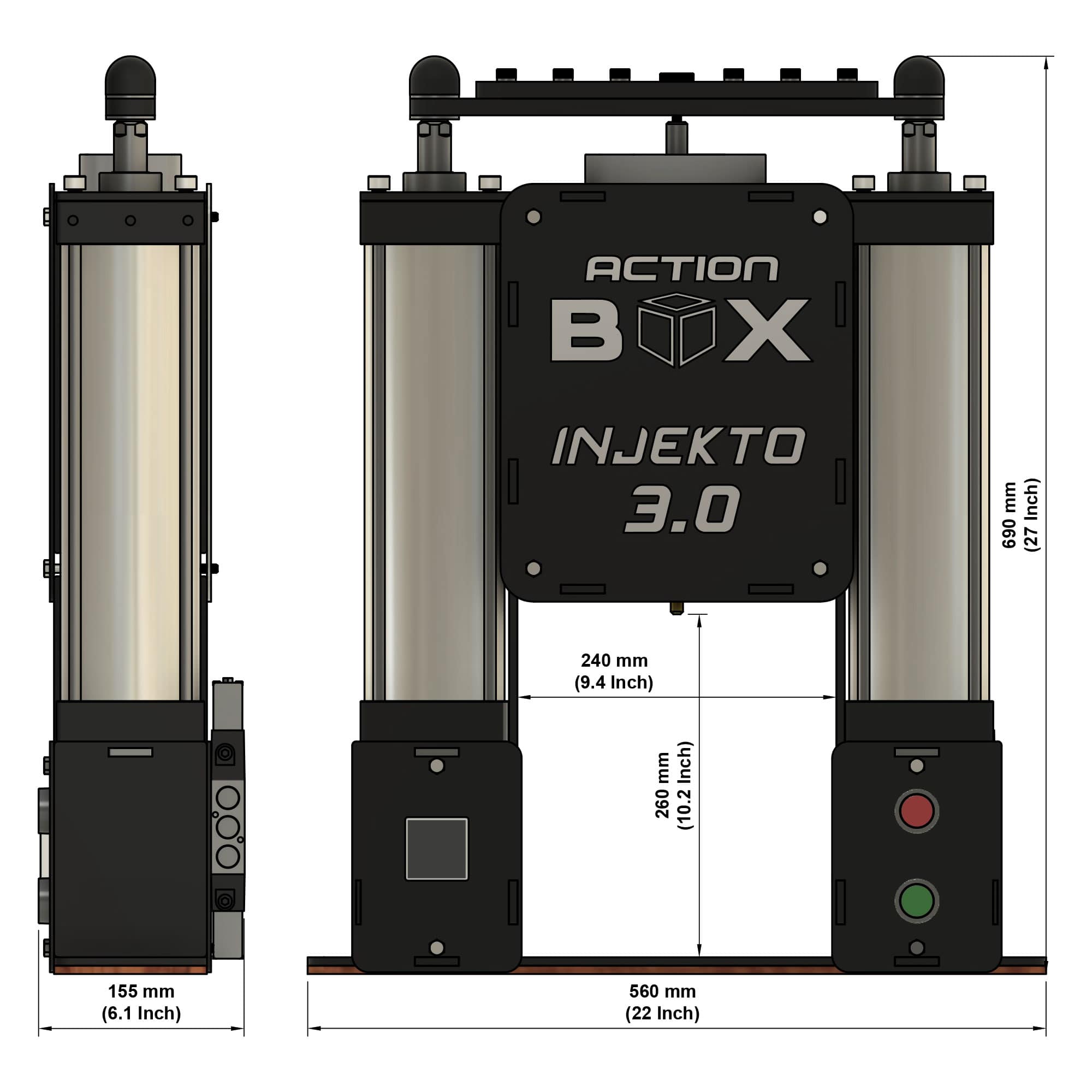

INJEKTO 3 | Plastic Injection Molding Machine | Full Kit

$2,599.00 USD